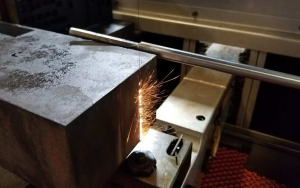

Wire Cutting: A Key Process in High-Precision Metal Machining

1.Introduction to Wire Cutting

Wire cutting uses a continuously moving thin metal wire as an electrode to corrode metal through pulse discharge. It can process complex and high-precision parts, and is suitable for materials such as cemented carbide and die steel, with wide applications in mold manufacturing.

2.Main Process Types

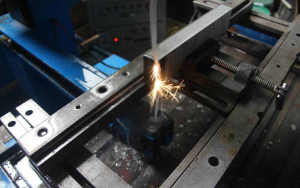

2.1 High-speed wire cutting: Uses molybdenum wire, which can be reused, with a wire feeding speed of 8-10m/s. It has high efficiency and low cost, and is suitable for processing parts with moderate precision.

2.2 Low-speed wire cutting: Uses copper wire, which is for one-time use, with a wire feeding speed lower than 0.2m/s. It has high precision and good surface quality, and is suitable for processing high-precision and complex parts.

2.3 Medium-speed wire cutting: Combines the characteristics of high-speed and low-speed wire cutting, with a wire feeding speed between the two. It improves processing precision and surface quality through multiple cuts, has high cost performance, and is suitable for processing small and medium batches of precision parts.

3.Technical Advantages

The precision can reach ±0.001mm; it can process complex special-shaped contours; there is no obvious cutting force, avoiding workpiece deformation; it has strong adaptability to the processing of high-hardness and high-strength materials; the degree of automation is high, ensuring stable processing.

4.Industry Applications

Mold manufacturing: Processing of various stamping dies, plastic molds, etc.; Aerospace: Processing of precision and complex components; Automotive industry: Processing of high-precision mold parts and engine components; Medical devices: Processing of precision surgical instruments, etc.; Electronics industry: Processing of precision molds and micro parts.