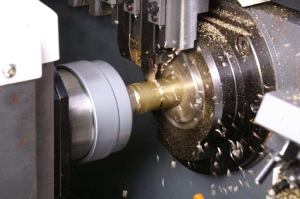

The application of turning in the manufacture of medical devices

In medical device manufacturing, turning, with high precision and stability, is key for critical components, ensuring safety.

In surgical instruments, scalpel handles and hemostat pins need turning for dimensions. Handle turning ensures grip, finish and prevents bacteria; pin turning affects hemostat function, with micron precision aiding surgery.

Implantables demand stricter turning. Titanium parts like artificial joint heads and nails need extreme accuracy via turning. Joint head turning reduces friction; nail turning balances strength and stability for fixation.

Medical equipment parts (e.g., ventilator/monitor shafts) rely on turning for stable, accurate high-speed operation, avoiding failures and protecting patients.

In short, turning is vital in medical device making, underpinning performance and safety.