Sheet Metal Fabrication Services

- Prototype & Serial Manufacturing

- Aluminium, Steel, Stainless Steel

- Lead Time as Fast as 3 Day

- Tolerances down to +/- 0.01mm

- Quick quote within 2 hours

Start A New Sheet Metal Quote

Upload Your Design- All uploads are secure and confidential

Our Sheet Metal Fabrication Services

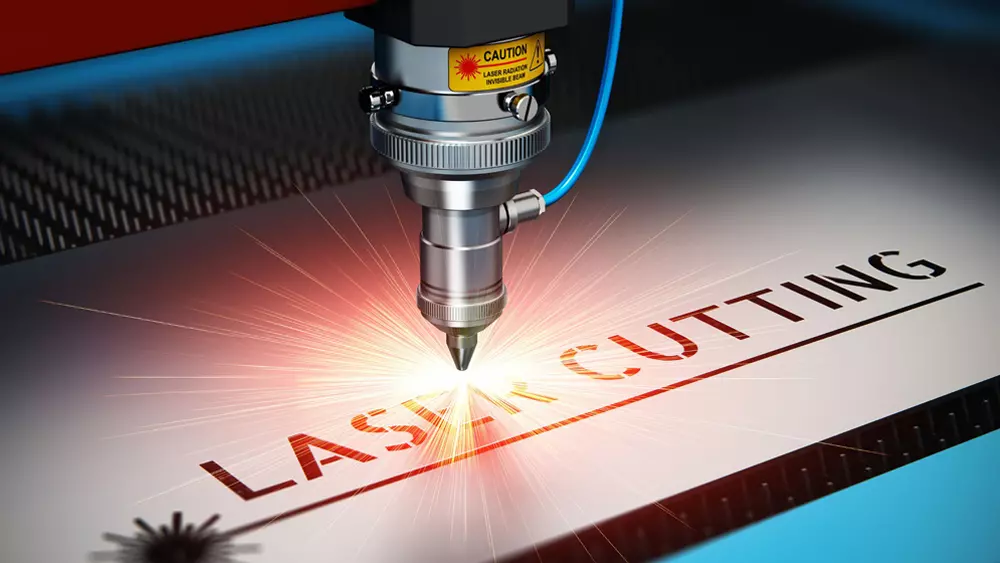

Laser Cutting

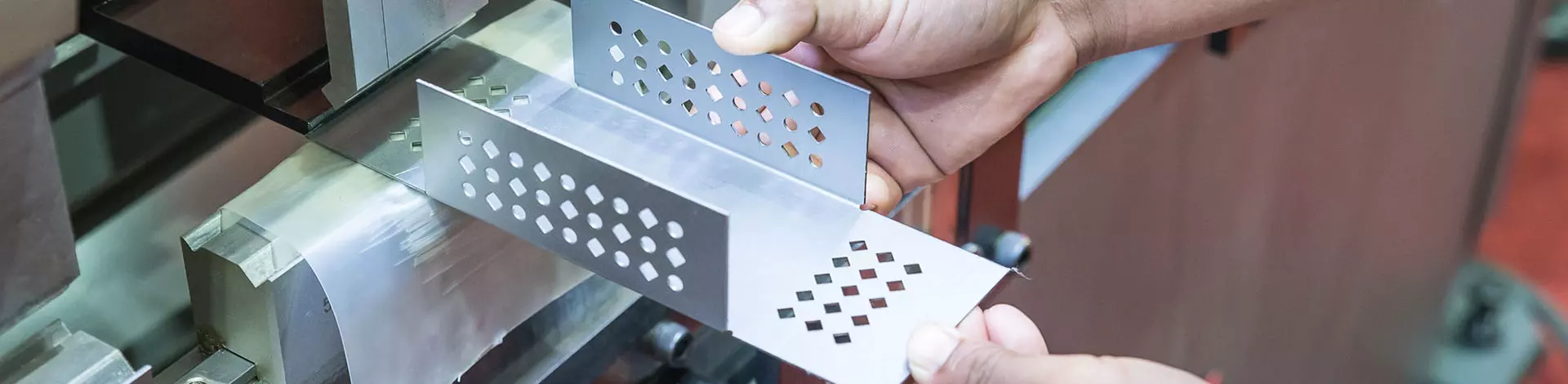

Bending

Welding

Sheet Metal Materials

Aluminum

- Aluminium 5052 / Al-Mg2.5

- Aluminium 5083 / Al-Mg4.5Mn

- Aluminium 5754 / Al-Mg3

- Aluminium 6060 / Al-MgSi

- Aluminium 6061 / Al-Mg1SiCu

- Aluminium 6082 / Al-Si1Mg

- Aluminium 7075 / Al-Zn6MgCu

Steel

- Steel S235JR

- Steel S275JR

- Steel S235J2 / S235J2G4

- Steel S235J2 / S235J2G4, pickled and oiled

- Steel DC01

- Steel C45 / EN8

- Steel S355J2G3

- Steel XC48H1 / C45E

- Steel X153CrMo12 / SKD11, annealed

- Steel 100MnCrW4 / SKS3, annealed

- Steel 25CrMo4 / 708A25

- Steel 42CrMo4 / EN19

Stainless steel

- Stainless Steel 304 / X5CrNi18.10

- Stainless Steel 316L / X2CrNiMo17-12-2

Copper

- Copper C110, 101, CU ETP, CU OFE

Brass

- Cz121, C38500, 2.0401, CuZn39Pb3, Brass C360, 2.0375, CuZn36Pb3

- 319 grade 2

Finishing Options

Bead blasting

Final result:

- Slightly grainy in the touch

- Uniform, matte or satin-like appearance

Anodising (type II)

Available colors:

- Black / Blue / Gold / yellow / Green / Grey / Natural / Orange / Red / Yellow / Purple / Customer Color(RAL)

Hardcoat anodising (type III)

Available colors:

- Black / Grey / Natural

Powder coating

Available colors:

- Black

Manufacturing Specifications & Capabilities

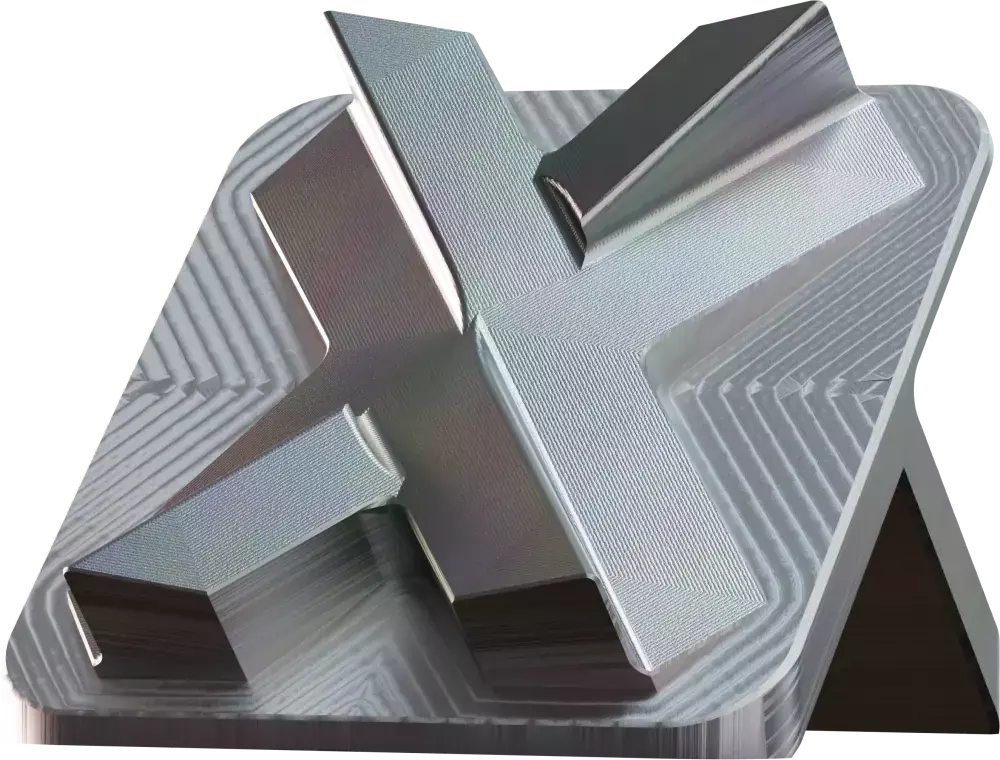

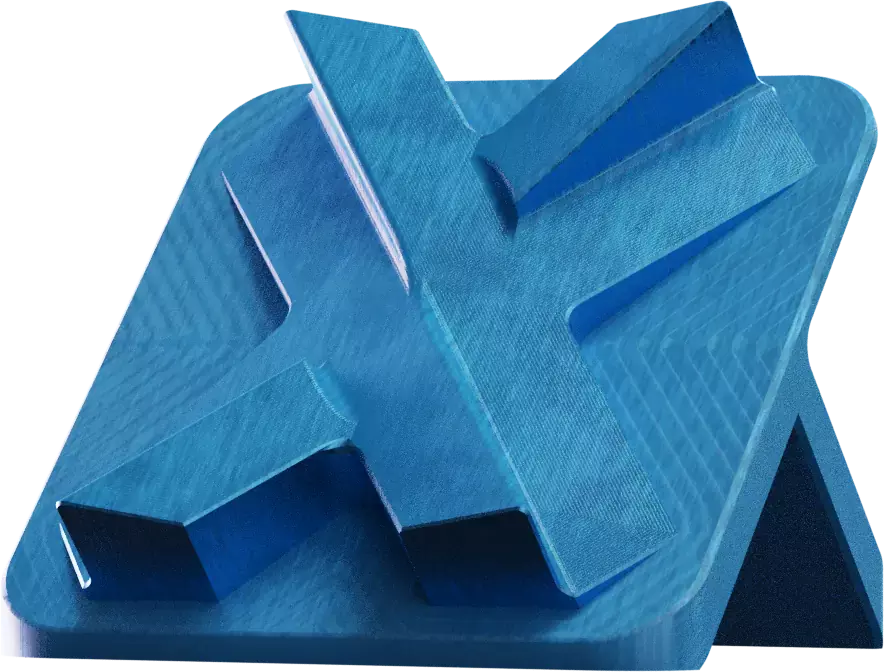

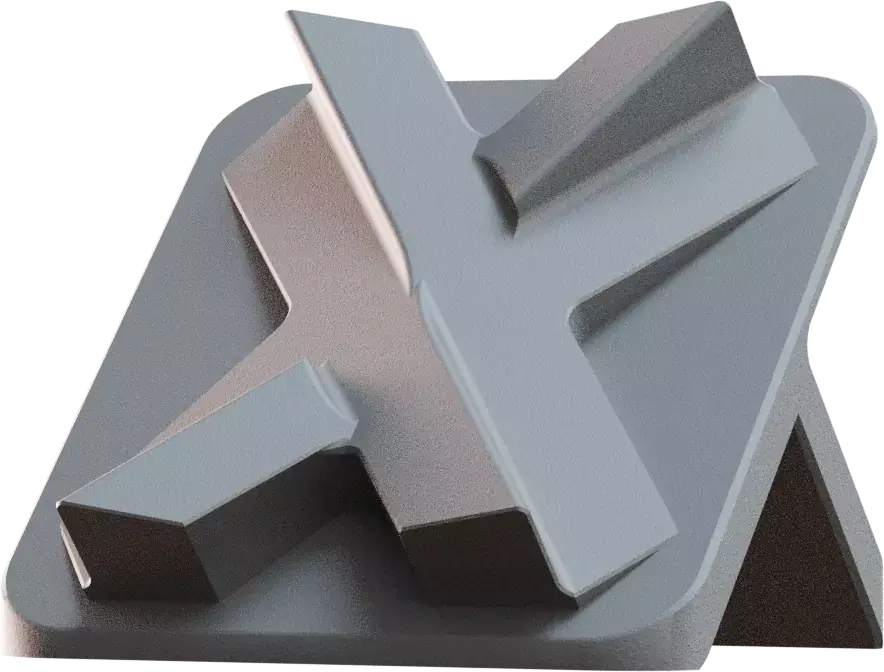

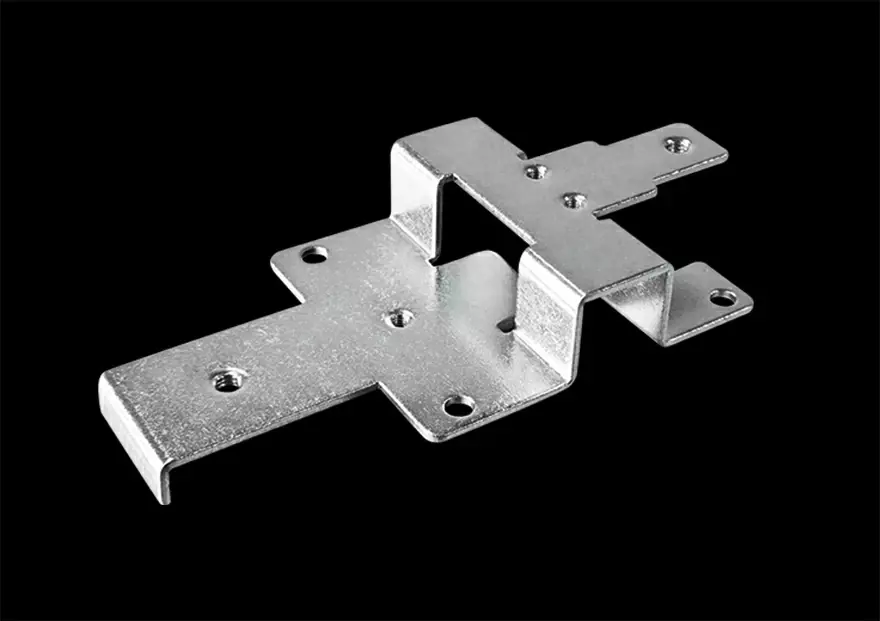

Gallery Of Sheet Metal Fabrication Parts

Advantages of Ordering Sheet Metal Parts

Industrial Applications

Frequently Asked Questions

What kind of sheet metal fabrication services do you provide?

We provide customized sheet metal fabrication services, including sheet metal cutting, bending, punching, welding and assembly processes, to meet customer specific requirements.

Do you accept small batch orders?

Yes, we accept small batch orders. Our sheet metal fabrication equipment and processes can adapt to orders of various sizes, from small batches to large-scale production.

What materials can you handle?

We can handle various common sheet metal materials, such as steel, stainless steel, aluminum, copper, etc. If you have special material requirements, we can evaluate and discuss them.

How can I provide you with my design drawings?

You can send us the design drawings in electronic format (such as CAD files). Our team will carefully review your design and work with you to ensure accuracy.Please provide detailed specifications and requirements, and we will produce customized parts or products according to your needs. Upload CAD files

Do you provide sample production?

Yes, we can make samples according to the customer’s requirements. Sample production usually requires additional time and cost, but it can ensure that the final product meets your needs.

What is your delivery time?

The delivery time depends on the size and complexity of the order. We will provide specific delivery time after order confirmation. We will do our best to meet the customer’s requirements and inform you of the delivery progress in a timely manner.

How to obtain a quotation and place an order?

You can contact us by phone, email, or online to provide detailed information about your project requirements. Our sales team will work with you to provide you with a quotation and assist you in completing the order process.