Formative Manufacturing Services

- Rapid quoting within 24-48 hours

- 50+ available materials (plastics, elastomers, metals)

- Custom prototypes, tooling and serial production of parts

- Mould fabrication as a service

Start A New Quote

Upload Your Design- All uploads are secure and confidential

Moulded and Cast Parts

Injection Moulding

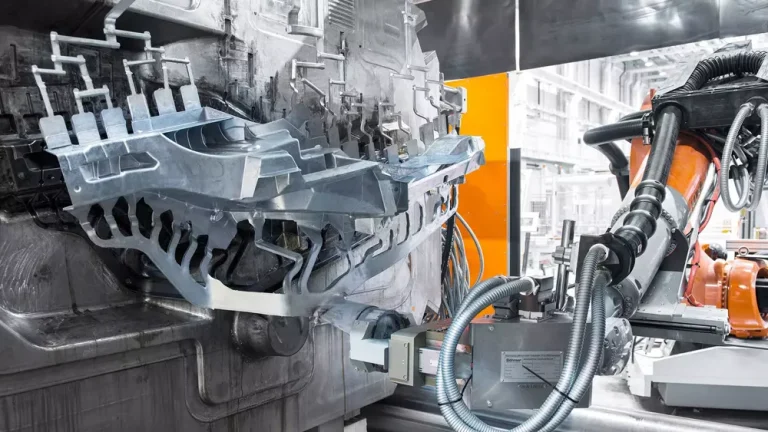

Die Casting

Vacuum Casting

Compression Moulding

Formative Manufacturing Materials

Aluminium

- Aluminium 46100 / ADC12 / A383 / Al-Si11Cu3

- Aluminium 46500 / A380 / Al-Si8Cu3

Elastomers & Rubbers

- PVC

- Silicone

- T0387, Rubber Transparent

- TPE (Elastomer)

- TPV (rubber)

- UPX8400, Rubber-like

Rigid plastics

- ABS

- ABS-like plastics

- PU8150, ABS-like

- PU8260, ABS-like

- PU8263, ABS-like

- PX100, ABS-like

- PX118, ABS-like

- PX215, ABS-like

- UP4280, ABS-like

- Acrylic (PMMA)

- HDPE

- LDPE

- Nylon 6 / PA 6

- Nylon 66 / Nylon 6/6

- PBT

- PC (Polycarbonate)

- PC-like plastics

- PU8098, PC-like

- PX510, PC-like

- UP6160, PC-like

- PC-ABS Polycarbonate

- PC-ABS-like plastics

- PX223HT, PC-ABS-like

- PC-PBT

- PEEK

- PEI (Ultem)

- PET

- PLA

- Polyethylene (PE)

- Polypropylene (PP)

- Polystyrene (PS)

- POM / Delrin acetal

- PMMA / Acrylic-like plastics

- PX5210HT, PMMA / Acrylic-like

- UPX5210, PMMA / Acrylic-like

- X522HT, PMMA / Acrylic-like

- PPE-PS

- PPS

- PP-like plastics

- PU8570, PP-like

- 8550, PP-like

- UP5690, PP-like

- PSU

Zinc

- Zamak 2

- Zamak 3

- Zamak 4

- Zamak 5

- Zamak 7

Finishing Options for Moulded and Cast Parts

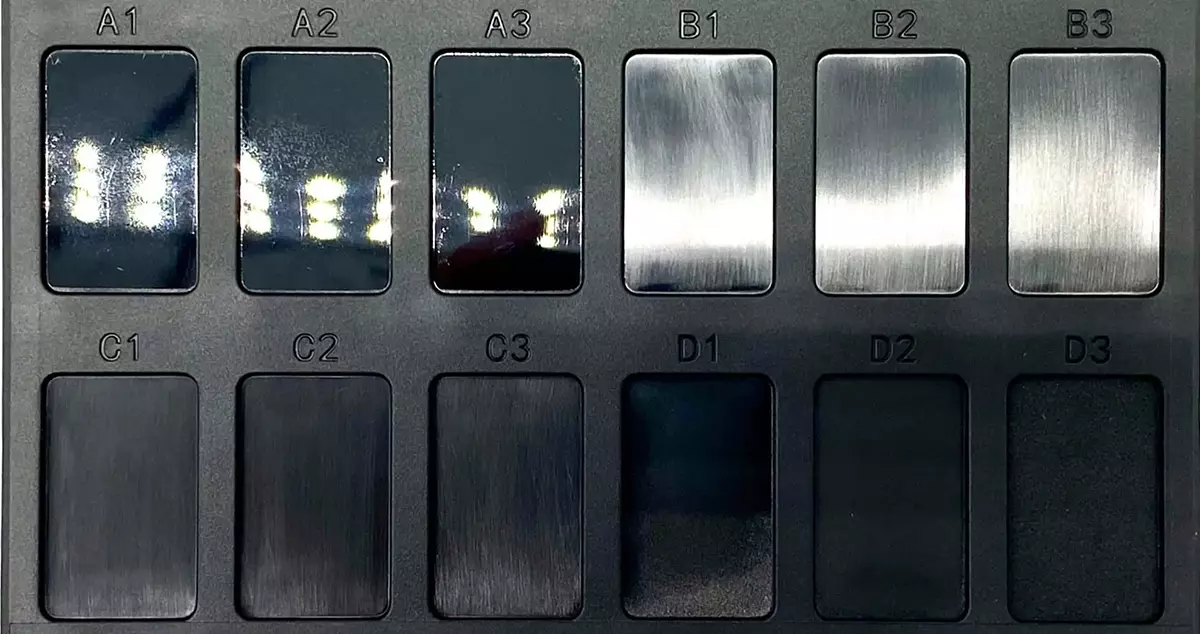

SPI

Final result:

- Heavily polished, to semi-gloss to fine and coarse matte depending on the selection

- A1, A2, A3, B1, B2, B3, C1, C2, C3, D1, D2, D3

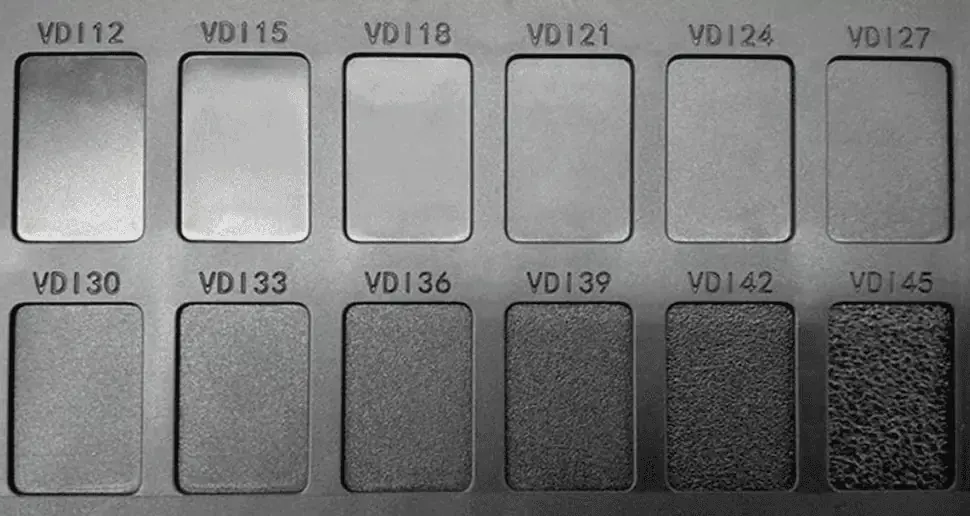

VDI

Final result:

- Fine-to-coarse grain depending on the selection

- VDI12, VDI15, VDI18,VDI21, VDI 24, VDI27, VDI30, VDI33, VDI36, VDI39, VDI42, VDI45

Anodising (Type II)

Notes: Aluminium is typically anodised.

Final result:

- Anodised coatings are not electrically conductive

Spray painting

Available colors:

- Black

- Custom colour (RAL)

Comparison of our Formative Manufacturing Capabilities

Formative Manufacturing Projects

Advantages of Ordering Moulding & Cast Parts

Industrial Applications

Frequently Asked Questions

What type of plastic injection molding can you handle?

We can handle various types of plastic materials, including common ABS, PP, PE, PC, etc. Based on your needs and application scenarios, we will choose the most suitable material for you.

Can you provide product design services?

Yes, we can provide product design services. We have an experienced design team that can help you design and develop products from concept to reality.

Do you accept small batch orders?

Yes, we accept small batch orders. We understand that different customers have different needs, whether it’s mass production or small batch customization, we can meet your requirements.

How long is your production cycle?

The production cycle varies based on project complexity and order volume. We will do our best to complete your order in the shortest possible time. After confirming the design and requirements, we will provide you with the estimated production cycle.

Can you handle the design file format I provided?

Yes, we can handle various design file formats, such as CAD, SolidWorks, etc. Please provide us with your design documents in an acceptable format.

What information do we need to provide to obtain a quote?

In order to obtain an accurate quotation, we need you to provide the product’s design drawings, size requirements, material selection, and estimated order quantity.