CNC Turning Services

- CNC Milled Parts Online in the QuickMachine

- Aluminium, Steel, Copper, Polymers & More

- Lead Time as Fast as 3 Day

- Tight tolerance of +/- 0.005mm

- Free DFM feedback

Start A New CNC Turning Quote

Upload Your Design- All uploads are secure and confidential

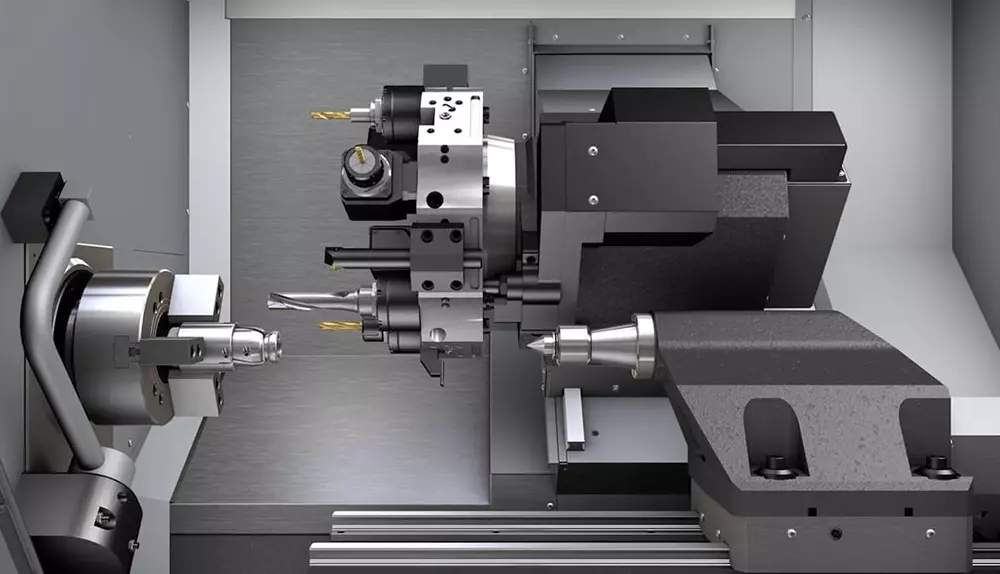

Robust CNC Turning Services

Our machine learning-trained technology also provides instant manufacturability feedback to ensure that your part fits the requirements you need and is optimized for the CNC turning process. Our on-demand manufacturing platform can deliver high-quality metal or plastic turned parts in any amount from a single prototype up to hundreds of thousands of parts.

Manufacturing precision turning parts on demand for your project, covering the production of small to large parts. With advanced technology and professional technicians, as well as the ability to customize personalized products, you can safely choose QuickMachine as your CNC turning service provider.

QuickMachine provides you with the capacity and capabilities for your project needs, while also delivering the most competitive pricing and lead times.

CNC Turning Materials

Aluminum

- Aluminium 2007 / Al-CuMgPb

- Aluminium 2017A / Al-Cu4Mg

- Aluminium 6060 / Al-MgSi

- Aluminium 6061 / Al-Mg1SiCu

- Aluminium 6082 / Al-Si1Mg

- Aluminium 7075 / Al-Zn6MgCu

Steel

- Steel S235JR

- Steel EN8 / 080M46 / C45

- Steel EN8D / C40

- Steel S355J2G3

- Steel AISI 02 Tool Steel / 90MnCrV8

- Steel 805M20 / 16MnCr5

- Steel 708A25 / 25CrMo4

- Steel EN19 / 708M40 / 42CrMo4

Stainless steel

- Stainless Steel 303 / X10CrNiS18-9

- Stainless Steel 304 / X5CrNi18.10

- Stainless Steel 304L / X2CrNi18-9

- Stainless Steel 316L / X2CrNiMo17-12-2

- Stainless Steel 316Ti / X6CrNiMoTi17-12-2

Copper

- Copper C101 /E-Cu58 / E-Cu57

Brass

- Brass Ms58 / CuZn39Pb3

Titanium

- Titan Grade 2

- Titan Grade 5 / Ti-6Al-4V

Rigid plastics

- ABS

- Acrylic

- PC (Polycarbonate)

- PEEK

- PEEK glass-filled

- Polypropylene (PP)

- POM / Delrin acetal

- PTFE / Teflon

- PVDF / Polyvinylidene fluoride

- UHMW PE / Ultra-high-molecular-weight polyethylene

Finishing Options

Bead blasting

Final result:

- Slightly grainy in the touch

- Uniform, matte or satin-like appearance

Anodising (type II)

Available colors:

- Black / Blue / Gold / yellow / Green / Grey / Natural / Orange / Red / Yellow / Purple / Customer Color(RAL)

Hardcoat anodising (type III)

Available colors:

- Black / Grey / Natural

Powder coating

Available colors:

- Black

Gallery Of CNC Turning Parts

Advantages of CNC Turning

Industrial Applications

Frequently Asked Questions

What is CNC turning?

CNC turning is a manufacturing process that involves the use of computer-controlled machines to create precise and complex parts. During CNC turning, a workpiece is rotated while a cutting tool removes material from the workpiece to create the desired shape.

What materials can be used for CNC turning?

We work with a variety of materials, including aluminum, brass, copper, stainless steel, and titanium. If you have a specific material requirement, please let us know and we will do our best to accommodate your needs.

What types of finishes can you provide?

We offer a variety of finishes, including anodizing, plating, powder coating, and painting. If you have a specific finish requirement, please let us know and we will do our best to accommodate your needs.

What is your quality control process?

We have a rigorous quality control process that involves multiple inspections and tests throughout the manufacturing process. We use advanced inspection and testing equipment to ensure that all parts meet or exceed industry standards.

How can I get started with CNC turning?

To get started with CNC turning, you should:

1. Determine your requirements for the parts you need.

2. Choose a reputable CNC turning service provider.

3. Submit your design files and specifications to the service provider.

4. Review and approve a quote for the project.

5. Receive and inspect the finished parts.

we are committed to providing our customers with the highest quality turning parts machining services. Contact us today to learn more about our capabilities and how we can help meet your turning parts machining needs.

What is your minimum order quantity?

We do not have a minimum order quantity. Whether you need a single part or thousands of parts, we are happy to work with you.

What is your pricing structure?

Our pricing is based on the complexity and quantity of the parts being manufactured. We will provide you with a detailed quote when you submit your order.

Do you offer design assistance?

Yes, we have a team of experienced engineers who can assist you with design and prototyping. We can work with you to optimize your designs for manufacturability and efficiency.

What is your warranty policy?

We offer a warranty on all of our products. If you experience any issues with our products, please contact us and we will work with you to resolve the issue.

How do I submit an order?

You can submit an order by contacting us directly or through our website. We will work with you to ensure that your order is submitted correctly and that you receive the parts you need on time and within budget.