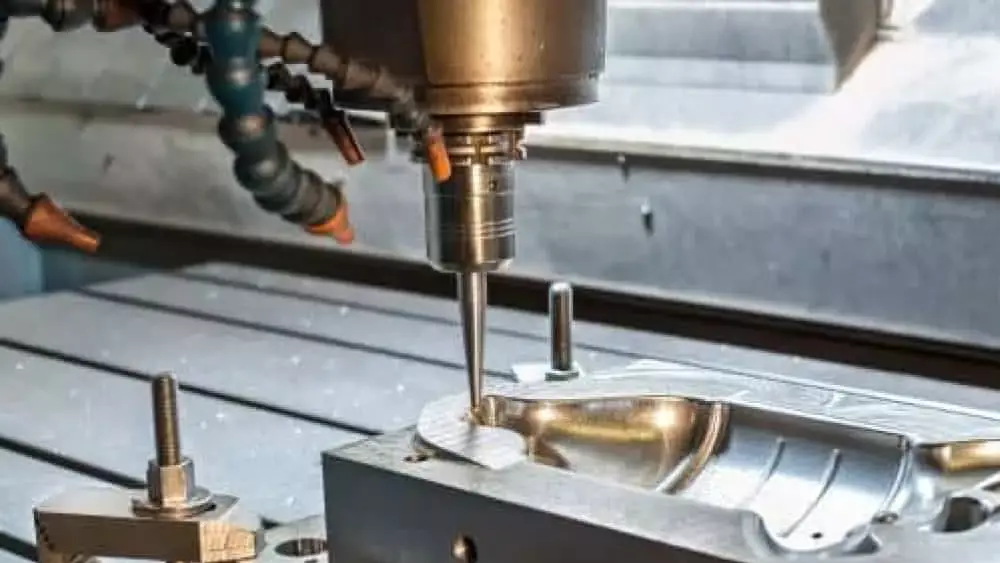

5 Axis CNC Machining Services

- CNC Milled Parts Online in the QuickMachine

- Aluminium, Steel, Copper, Polymers & More

- Lead Time as Fast as 3 Day

- Tight tolerance of +/- 0.005mm

- Custom precise, complex parts

Start A New 5 Axis Milling Quote

Upload Your Design- All uploads are secure and confidential

Our 5 Axis CNC Machining Capabilities

Simultaneous 5 Axis CNC Machining

3+2 Axis CNC Machining

5 Axis CNC Machining Materials

Aluminum

- Aluminium 2007 / Al-CuMgPb

- Aluminium 2017A / Al-Cu4Mg

- Aluminium 6060 / Al-MgSi

- Aluminium 6061 / Al-Mg1SiCu

- Aluminium 6082 / Al-Si1Mg

- Aluminium 7075 / Al-Zn6MgCu

Steel

- Steel S235JR

- Steel EN8 / 080M46 / C45

- Steel EN8D / C40

- Steel S355J2G3

- Steel AISI 02 Tool Steel / 90MnCrV8

- Steel 805M20 / 16MnCr5

- Steel 708A25 / 25CrMo4

- Steel EN19 / 708M40 / 42CrMo4

Stainless steel

- Stainless Steel 303 / X10CrNiS18-9

- Stainless Steel 304 / X5CrNi18.10

- Stainless Steel 304L / X2CrNi18-9

- Stainless Steel 316L / X2CrNiMo17-12-2

- Stainless Steel 316Ti / X6CrNiMoTi17-12-2

Copper

- Copper C101 /E-Cu58 / E-Cu57

Brass

- Brass Ms58 / CuZn39Pb3

Titanium

- Titan Grade 2

- Titan Grade 5 / Ti-6Al-4V

Rigid plastics

- ABS

- Acrylic

- PC (Polycarbonate)

- PEEK

- PEEK glass-filled

- Polypropylene (PP)

- POM / Delrin acetal

- PTFE / Teflon

- PVDF / Polyvinylidene fluoride

- UHMW PE / Ultra-high-molecular-weight polyethylene

Finishing Options

Bead blasting

Final result:

- Slightly grainy in the touch

- Uniform, matte or satin-like appearance

Anodising (type II)

Available colors:

- Black / Blue / Gold / yellow / Green / Grey / Natural / Orange / Red / Yellow / Purple / Customer Color(RAL)

Hardcoat anodising (type III)

Available colors:

- Black / Grey / Natural

Powder coating

Available colors:

- Black

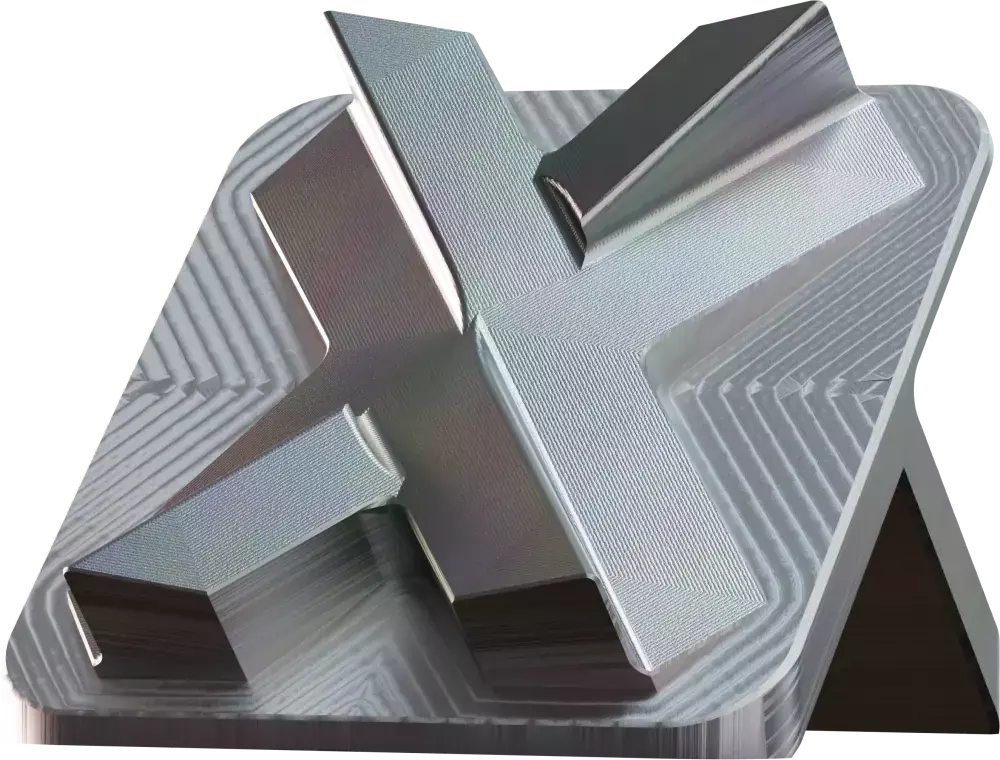

Gallery Of 5 Axis Machining Parts

Advantages of 5 Axis Machining

Industrial Applications

Frequently Asked Questions

What 5 axis CNC machining services do you offer?

We offer all types of 5 axis CNC machining services, including aluminum alloy machining, copper machining, stainless steel machining, titanium alloy machining and composite machining. We can also tailor the service according to your requirements, if you need custom processing, please contact our customer service personnel

What is the maximum size for 5 axis CNC machining?

The size of 5 axis CNC machining mainly depends on the working area of the machine and the size of the processed materials. We can provide various sizes of machining to meet your specific needs.

Why choose 5 axis machining?

5 axis machining can handle some complex parts, such as curved surfaces, complex convex shell parts, and parts requiring very high precision. At the same time, 5 axis machining can complete the machining of multiple faces through a single clamping, thus improving work efficiency.