CNC Machining Services

- Manufacturing on demand

- Lead times starting from 3 days

- Over 30 materials and 20+ finishes quoted instantly

- Tolerances down to +/- 0.005mm

- Dedicated account manager and engineering support

- Highest standards of data protection

Start Your CNC Machining Quote

Upload Your Design- All uploads are secure and confidential

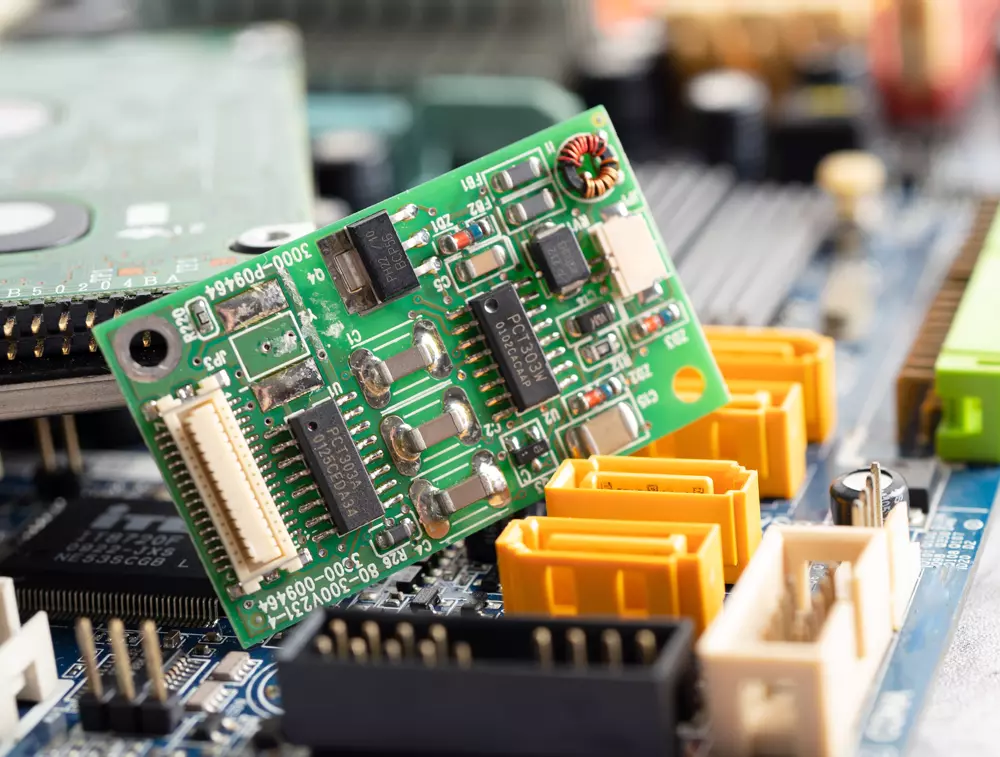

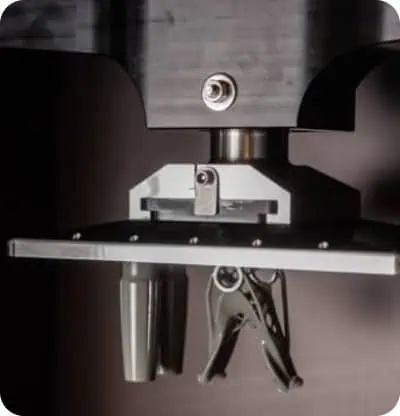

CNC Machining Capabilities

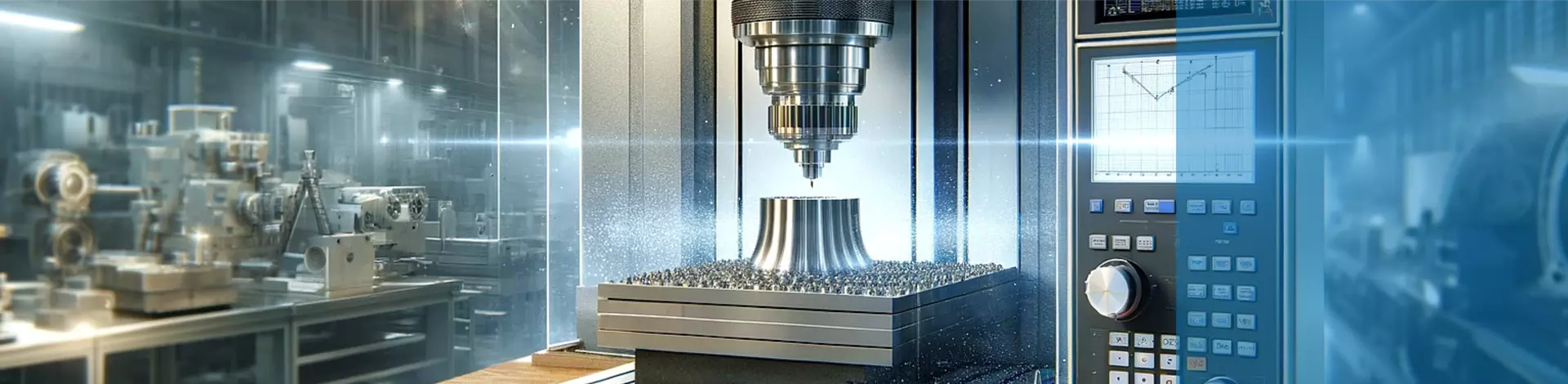

CNC Milling

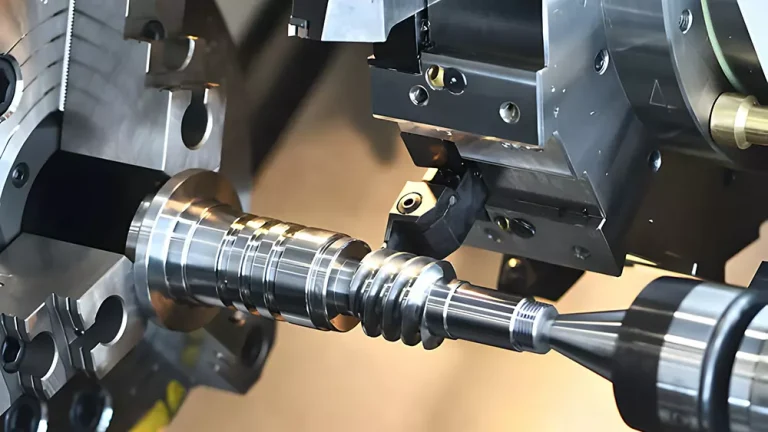

CNC Turning

5 Axis CNC Machining

CNC Machining Materials

Aluminium

- Aluminium 6061 / 3.3211 / Al-Mg1SiCu

- Aluminium 5083 / 3.3547 / AlMg4.5Mn

- Aluminium 2024

- Aluminium 6082 / 3.2315 / Al-Si1Mg

- Aluminium 7075 / 3.4365 / Al-Zn6MgCu

Steel

- Steel 1.0038 / S235JR

- Steel 1.0503 / C45

- Steel 1.0511 / C40

- Steel 1.0570 / S355J2G3

- Steel 1.2842 / 90MnCrV8

- Steel 1.7131 / 16MnCr5

- Steel 1.7218 / 25CrMo4

- Steel 1.7225 / 42CrMo4

- Mould Steel 1.2738

Stainless steel

- Stainless Steel 304L / 1.4307 / X2CrNi18-9

- Stainless Steel 316 / 1.4401 / X5CrNiMo17122

- Stainless Steel 304 / 1.4301 / X5CrNi18.10

- Stainless Steel 316L / 1.4404 / X2CrNiMo17-12-2

- Stainless Steel 316Ti / 1.4571 / X6CrNiMoTi17-12-2

Plastics

- ABS

- Acrylic

- Polypropylene (PP)

- PC (Polycarbonate)

- PEEK

- UHMW PE / Ultra-high-molecular-weight polyethylene

- PTFE / Teflon

- POM / Delrin acetal

Other metals

- Brass Ms58 / 2.0401 / CuZn39Pb3

- Copper E-Cu57 / 2.0060 / E-Cu58 / 2.0065

- Titanium Grade 2 / 3.7035

- Titanium Grade 5 / 3.7164 / 3.7165 / Ti-6Al-4V

CNC Machining Surface Finishing

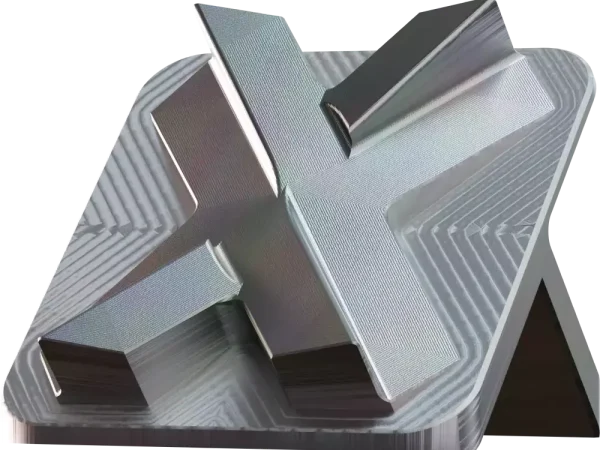

As-machined

Final result:

- Machining marks are visible

- Light surface scratches are visible

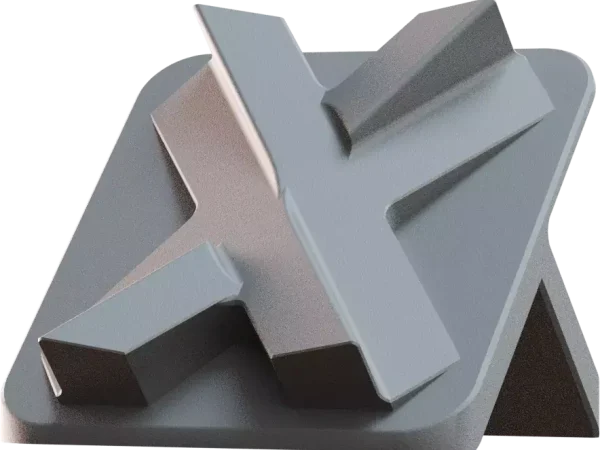

Bead blasting

Final result:

- Slightly grainy in the touch

- Uniform, matte or satin-like appearance

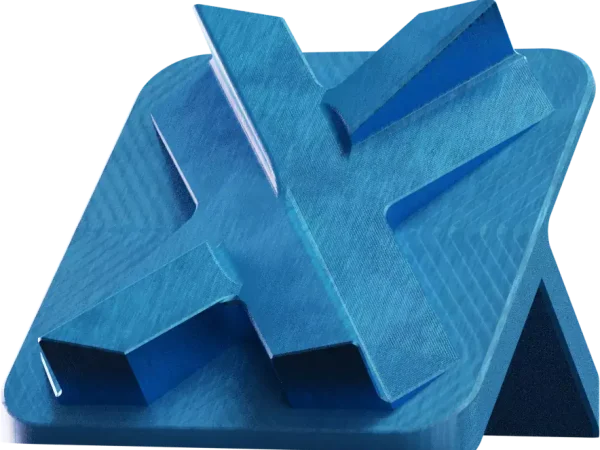

Anodising (type II)

Available colors:

- Black / Blue / Gold / yellow / Green / Grey / Natural / Orange / Red / Yellow / Purple / Customer Color(RAL)

Hardcoat anodising (type III)

Available colors:

- Black / Grey / Natural

CNC Machining Projects Made

Our Competitive Advantages

Industrial Applications

Frequently Asked Questions

What types of parts can be created using CNC machining?

CNC machining can be used to create a wide variety of cnc parts, from simple components to complex assemblies. cnc parts can be made in a range of sizes, shapes, and configurations, and can be customized to meet specific requirements.

Do you accept small batch orders?

Yes, we accept small batch orders. We have flexible production capabilities that can meet the personalized needs of customers, whether it is for small or large orders.

Do you have design support capabilities?

Yes, we have a professional design team and CAD/CAM software that can provide design support and advice, including manufacturability evaluation, process recommendations, and optimization of cnc parts. We work closely with customers to ensure that the design of the cnc parts meets the machining requirements.

What is your delivery time?

The delivery time varies depending on the complexity, quantity, and machining technology of the cnc parts. We will provide accurate delivery times based on customer order requirements and strive to deliver on time.

What is your precision CNC machining ability?

We have advanced CNC machine tools and a technical team that can achieve high-precision, complex shapes and fine details machining, meeting customer precision requirements.

Can you provide samples or prototype production?

Yes, we can provide samples or prototype production services according to customer requirements. We can process according to design drawings or samples to verify and confirm the quality and applicability of the cnc parts.

Do you have experience in handling complex part machining?

Yes, we have rich experience in machining complex parts, including Multiaxis machining, micro machining and surface machining.