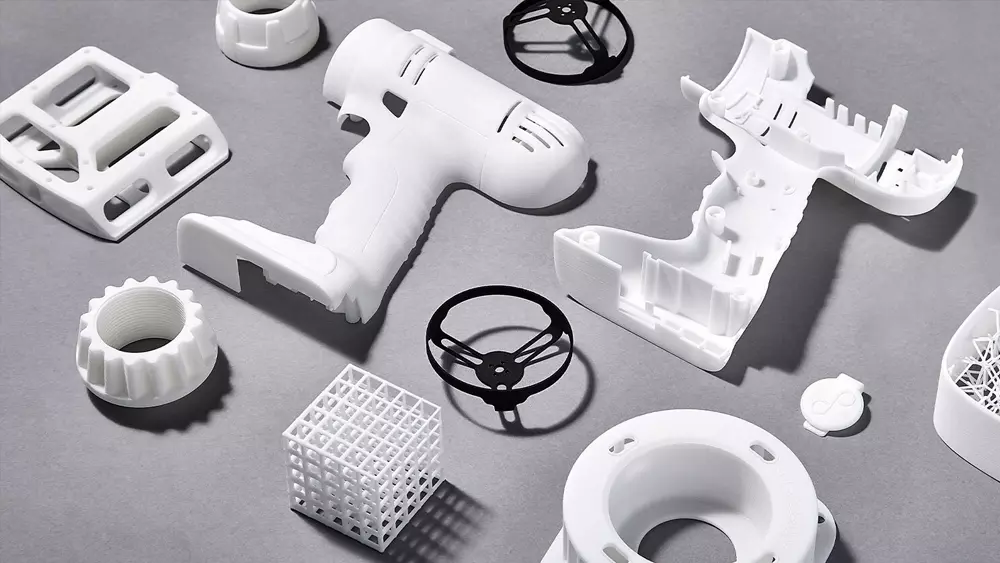

3D Printing Services

- Over 70 materials to choose from

- Fast 3D printing parts in 1 days

- 1-on-1 Technical Support

- Multiple processes: SLS, HP MJF, FDM, SLA, Carbon DLS™, PolyJet and DMLS

- Highest standards of data protection

Start A New 3D Printing Quote

Upload Your Design- All uploads are secure and confidential

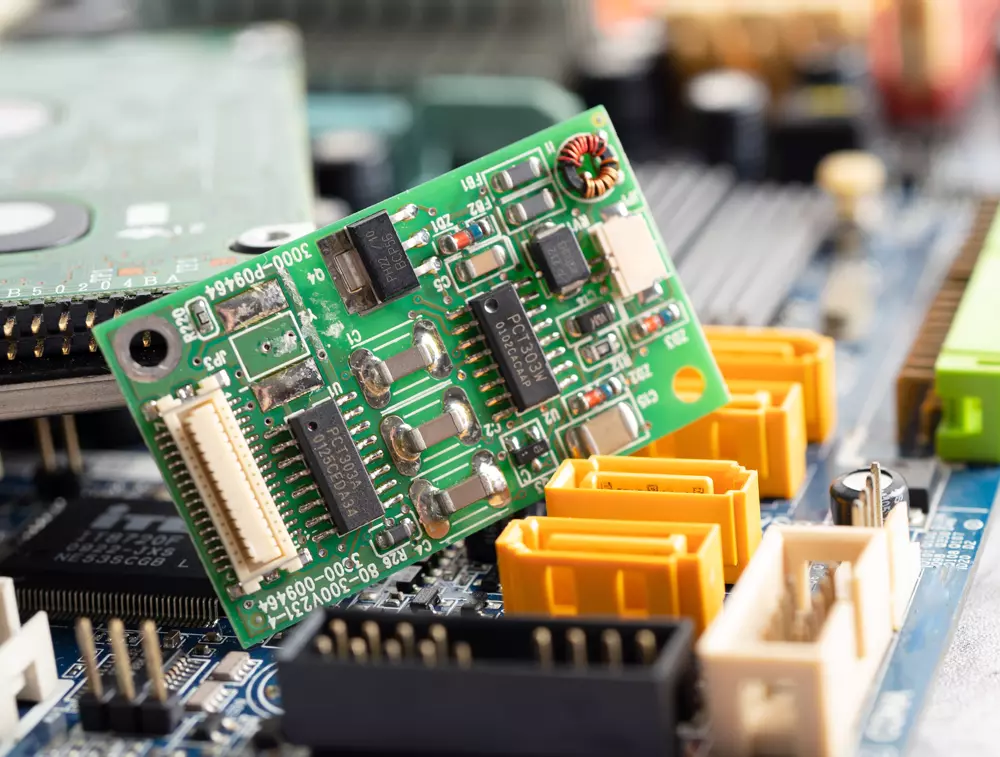

3D Printing Capabilities

SLA

SLS

FDM

3D Printing Materials

Plastics

- ABS

- ABS M30

- ABS-ESD7

- Alumide® / Nylon 12 (PA 12) filled with aluminium

- ASA

- CE 221 (Cyanatester)

- DPR 10

- EPX 82

- FPU 50

- Industrial Black, ABS-Like

- Industrial Grey, ABS-like

- Industrial Heat resistant, PC-like

- Industrial Transparent, ABS-like

- Industrial White, ABS-like

- Nylon 11 / PA 11

- Nylon 12 (PA 12) glass-filled

- Nylon 12 (PA 12) glass-filled

- Nylon 12 / PA 12 (FDM)

- Nylon 12 / PA 12 (SLS, MJF)

- Nylon 12 flame retardant / PA 2241 FR

- Nylon 12 full-colour / CB PA 12

Elastomers

- Flex TPU

- TPU (Polyurethane)

- EPU 40

- SIL 30

- True Silicone

Metals

- Aluminium Al-Si10Mg

- Cobalt chrome / CoCr

- Tool steel 1.2709 / MS1

- Stainless Steel 17-4PH / 1.4542 / X5CrNiCuNb16-4

- Stainless Steel 316L / 1.4404 / X2CrNiMo17-12-2

- Inconel 718

- Titan Grade 5 / 3.7164 / 3.7165 / Ti-6Al-4V

Surface Finishing Options For 3D Printing

Bead blasting

Notes: Semi-sintered surface particles remain on the part even after initial depowdering.

Final result:

- Slightly grainy in the touch

- Uniform, matte or satin-like appearance

Media tumbling

Final result:

- Smooth in the touch

- Satin-like matte appearance

Vapour smoothing

Final result:

- Smooth in the touch

- Glossy appearance

Quick clear

Final result:

- Enhanced transparency

3D Printing Standards

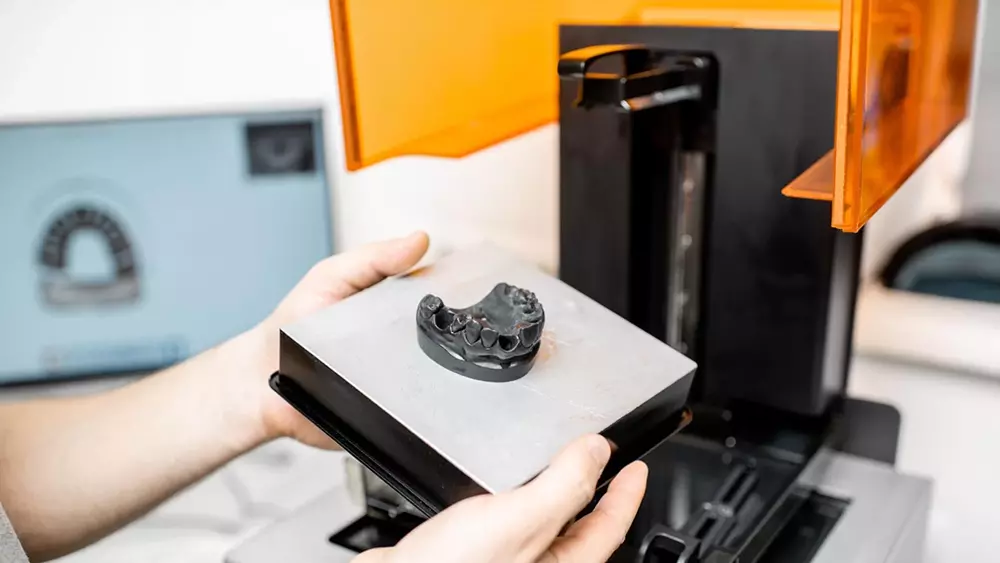

3D Printing Projects Made

Advantages of Ordering Sheet Metal Parts

Industrial Applications

Frequently Asked Questions

How can I choose the best 3D printing process for my project?

Selecting the right 3D printing process depends on your project’s requirements, such as material, part complexity, mechanical properties, and desired surface finish.

Can QuickMachine support both prototyping and mass production with 3D printing?

Yes, We specializes in both rapid prototyping and scalable mass production. For mass production, 3D printing is used to create complex geometries, reduce tooling costs, and enable efficient on-demand manufacturing. Suitable technologies include Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS) for high-volume plastic parts.

Do you assist with optimising part designs or selecting materials for 3D printing?

Yes, we offer support at multiple stages to ensure the best outcome for your project:

- Automated DFM feedback: Our instant quoting engine provides automated Design for Manufacturability (DFM) feedback, highlighting potential issues with your design and selected 3D printing process.

- Preliminary Manufacturability Check: Before production begins, we conduct a detailed review of your design. If any changes are necessary, we’ll reach out to collaborate on adjustments.

- Expert Guidance for corporate customers: Our 3D printing experts are available to help optimise your design and guide material selection based on your project’s specific needs.

Can you print multi-colour objects?

Yes, We can produce multi-colour objects using technologies like PolyJet and Multi Jet Fusion (MJF). Additionally, we offer post-processing options (painting and dyeing) to achieve custom colours and refine the finish of your 3D printed parts. Upload colour-supported file formats like OBJ or 3MF to get started.

What materials are available for 3D printing?

We offer 35 plastics, elastomers, and metals for instant quoting, each with unique properties such as strength, heat resistance, flame retardancy, flexibility, and more.

If you need a custom material, we can provide a quote within 24–48 hours. In most cases, if the material is supported by one of the 3D printing technologies we offer, we can produce it through our manufacturing network.

Which post-processing options do you offer for 3D printed parts?

We offers instant quotes for post-processing options such as bead blasting, media tumbling, vapor smoothing, dyeing in various colours, and spray painting with custom RAL colour options. These enhancements improve the appearance and functionality of your 3D-printed parts.

For any custom post-processing needs, we can provide a quote within 24–48 hours upon request.

What is the maximum size of an object I can print?

The maximum size of a 3D-printed object depends on the technology used. For example, with Fused Deposition Modeling (FDM), we can print parts up to 900x900x600 mm, while Stereolithography (SLA) supports maximum dimensions of 736x533x635 mm.

Can you 3D print in metal?

Yes, We offers metal 3D printing using Direct Metal Laser Sintering (DMLS) technology. We provide a variety of metals, including aluminium, stainless steel, tool steel, titanium, and inconel, suitable for creating prototypes and end-use parts.

Can you print transparent or translucent parts?

Yes, transparent and translucent parts can be printed using SLA (Stereolithography) technology with desktop and industrial transparent ABS-like materials, Flexible 80A Resin, and Silica Glass. These materials provide options for high resolution, smooth surfaces, stiffness, flexibility, and chemical resistance, catering to diverse applications.