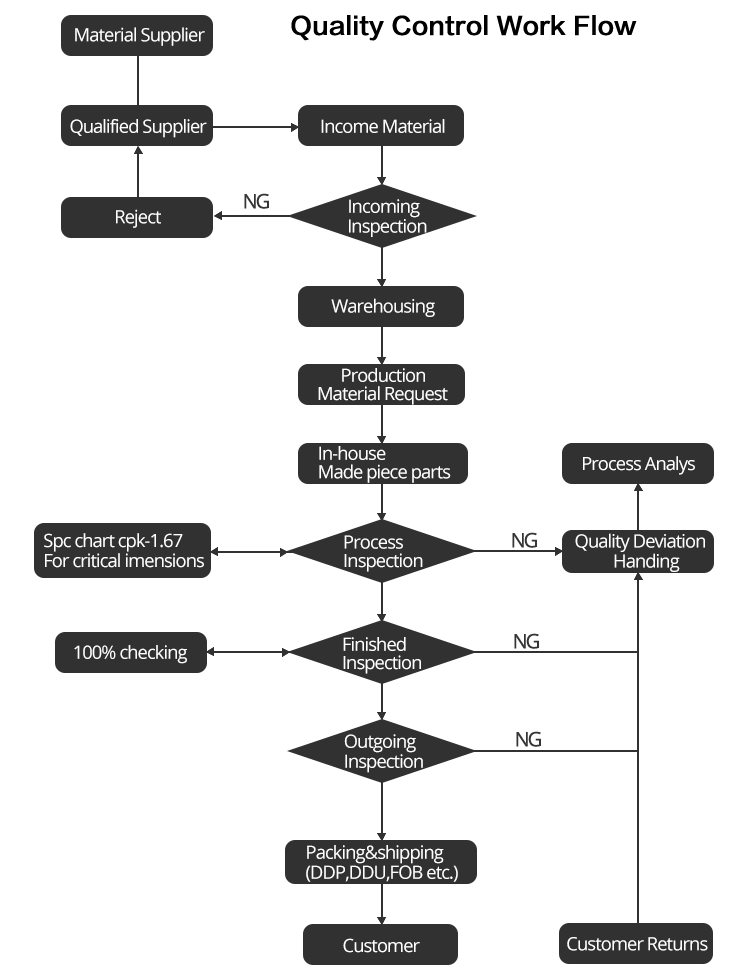

Quality Control

ISO Certified Manufacturer

Our approach strictly adheres to the ISO 9001-certified quality management system. We rely on a set of standardized production processes and work instructions, and employ cutting-edge testing equipment. This allows us to meticulously measure and inspect every stage of production, guaranteeing that your project meets rigorous quality standards. Our specialized manufacturing with quality control guarantees excellent service for customers worldwide.

Quality control of production

As your loyal supplier, we have strict manufacturing quality control in all manufacturing processes. To ensure these control processes can be implemented in place, we schedule the following steps:

- Part Design Checking

- Mold Design Control

- Raw material inspection

- Visual inspection

- FAI – First Article Inspection

- PPAP – Production Part Approval Process

- Mold Steel Hardness Inspection

- Mold Electrodes Inspection

- Mold Core and Cavity Steel Dimension Inspection

- Mold Pre-Assembly Inspection

- Mold Trial Report and Samples Inspection

- Pre-Shipment Final Inspection

- Export Product Package Inspection

Production quality control

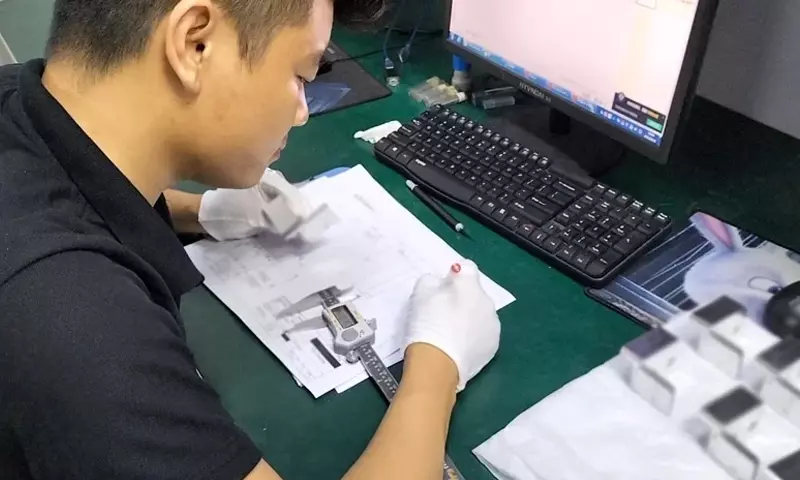

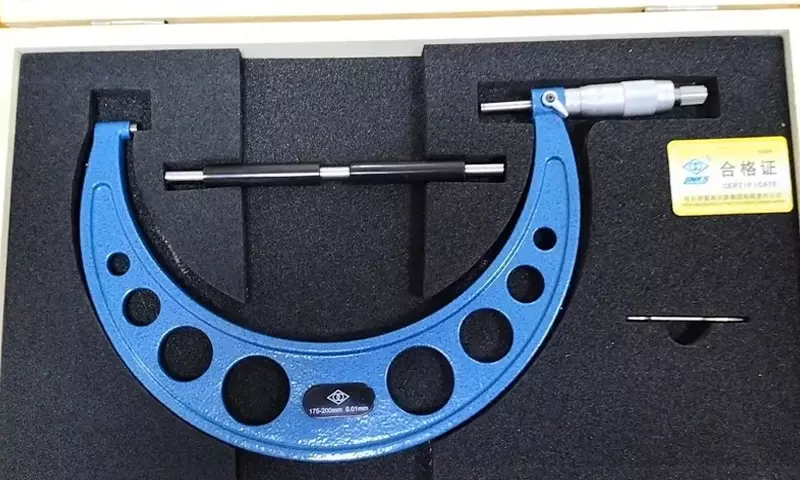

The quality assurance of QuickMachine CNC Machining defines the quality system requirements and goals for CNC precision machining solutions and services. It encompasses the management of raw material, assembly, product, and component quality, as well as production-related services and the oversight of management, manufacturing, and inspection processes.

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

Quote Now to Start Your CNC Machining Project

From raw material control to product inspection, we always adhere to the pursuit of excellent quality and deliver impeccable results for you. All information and uploads are secure and confidential.

Get Instant Quote