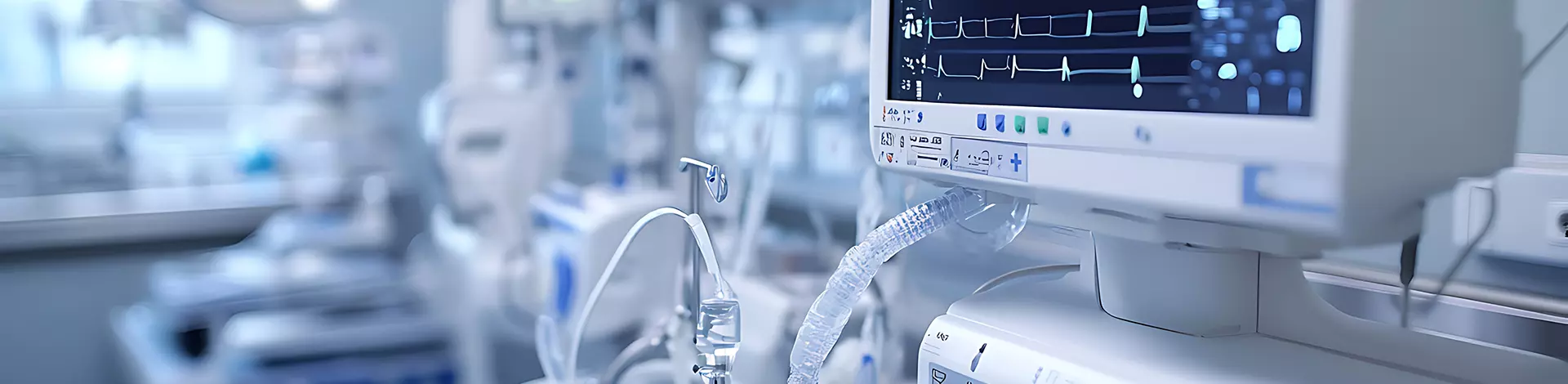

Quick Quotation

You can upload your design files at any time and receive DFM analysis feedback, pricing information, and estimated delivery time within two hours. Our efficient quotation speed will greatly improve your experience in medical parts manufacturing.