Aluminum Extrusion: Shaping Innovation for Modern Industry

Aluminum extrusion is a cornerstone manufacturing process that transforms aluminum alloys into complex, high-strength profiles with remarkable precision. At Quick Machine, we harness this versatile technology to deliver solutions across countless industries. Here’s how aluminum extrusion powers innovation and why it might be the ideal choice for your next project.

The Core Principle: Pushing Potential

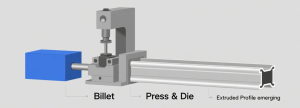

Imagine squeezing modeling clay through a shaped opening. Aluminum extrusion follows a similar principle, but at an industrial scale and elevated temperatures:

- Billet Heating:A solid cylindrical “billet” of aluminum alloy is heated to a specific plastic state (typically between 800°F – 925°F / 425°C – 500°C) – solid but malleable.

- The Extrusion Press:The heated billet is loaded into a powerful hydraulic press.

- Shaping the Future:A giant ram forces the softened aluminum through a precision-engineered steel die. The die’s opening defines the exact cross-sectional shape of the final profile.

- Cooling & Strengthening:The extruded profile emerges and is rapidly cooled (quenched) to lock in its mechanical properties. It then travels along a run-out table.

- Stretching & Cutting:The long profile is stretched to straighten it and relieve internal stresses, then precisely cut to specified lengths.

- Aging (If Required):Certain alloys undergo an aging process (like T5 or T6 temper) to achieve their optimal strength and hardness.

Why Choose Aluminum Extrusion? Key Advantages

This process offers unparalleled benefits that make it indispensable for designers and engineers:

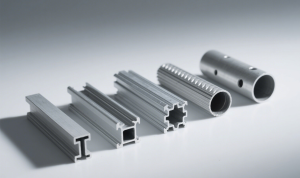

- Design Freedom:Create almost limitless complex cross-sections – solid, hollow, multi-void – impossible or prohibitively expensive with other methods. Integrate multiple features (channels, lips, snap-fits, screw bosses) into a single part.

- Lightweight Strength:Aluminum offers an exceptional strength-to-weight ratio. Extruded profiles provide structural integrity while minimizing weight – crucial for transportation, aerospace, and mobile applications.

- Material Efficiency & Sustainability:Extrusion minimizes waste compared to machining from solid blocks. Aluminum is highly recyclable (often containing significant recycled content) without losing quality, supporting circular economy goals.

- Cost-Effectiveness:Low per-part costs, especially for high volumes. Minimal secondary machining is often required. Consolidating multiple parts into one extrusion reduces assembly time and cost.

- Superior Surface Finish:Extruded profiles have an excellent natural finish, readily accepting anodizing, powder coating, painting, or other finishes for enhanced aesthetics and corrosion resistance.

- Excellent Thermal & Electrical Conductivity:Ideal for heat sinks, electrical enclosures, and busbars.

- Corrosion Resistance:Aluminum naturally forms a protective oxide layer, further enhanced by finishing processes.

Where Aluminum Extrusion Excels: Application Areas

The versatility of extruded aluminum makes it ubiquitous:

- Construction & Architecture:Window and door frames, curtain walls, structural frameworks, roofing systems, sunshades, bridges, handrails.

- Transportation:Automotive body structures, bumpers, roof rails, heat exchangers, EV battery enclosures. Aerospace components, rail carriages, truck trailers, marine structures.

- Electronics & Electrical:Heat sinks for computers/LEDs, housings, enclosures, chassis, busbars, cable management systems.

- Industrial Machinery & Automation:Machine frames, conveyor systems, guards, linear motion components, robotic arms, T-slot framing systems (like 80/20®).

- Consumer Goods:Furniture frames, ladders, sporting goods (bikes, golf clubs), appliances, lighting fixtures.

- Renewable Energy:Solar panel frames, mounting structures, wind turbine components.

Partner with Quick Machine for Your Extrusion Needs

At Quick Machine, we combine state-of-the-art extrusion capabilities with deep engineering expertise. From concept and die design through precision extrusion, fabrication, and finishing, we provide comprehensive solutions tailored to your exact specifications.

Ready to harness the power and potential of aluminum extrusion? Contact our team today to discuss how we can bring your innovative designs to life.