Quick Machine Machining: Processes and Applications

1.Introduction to Machining

Machining refers to the process of changing the external dimensions or performance of a workpiece through mechanical equipment, and it is an important link in mechanical manufacturing. It can precisely process various metal and non – metallic materials, and can obtain high dimensional accuracy and surface quality. It is especially suitable for the manufacture of parts with complex shapes and high precision requirements. Common processing materials include steel, cast iron, non – ferrous metals (such as aluminum, copper) and engineering plastics. Among them, steel is most widely used in the field of machining due to its good mechanical properties.

2.Main Process Types

2.1 Cutting Processing

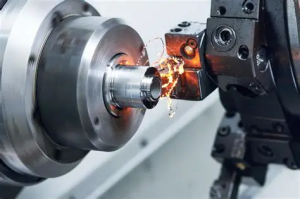

Remove excess material from the workpiece through the relative movement of the tool and the workpiece.

Including turning, milling, drilling, grinding, etc.

Typical applications: external circle processing of shaft parts, plane milling of box parts.

2.2 Special Processing

Process materials using electrical, optical, acoustic, thermal and other energy or chemical effects.

Including electrical discharge machining, laser machining, electrolytic machining, etc.

It can process materials and structures that are difficult to handle with traditional cutting.

2.3 Forming Processing

Obtain the required shape by making the material undergo plastic deformation or flow through external force.

Such as stamping, forging, etc.

It is often used for mass production of parts with relatively simple shapes.

3.Technical Advantages

High processing accuracy: It can reach micron – level or even nanometer – level accuracy, meeting the requirements of high – precision parts.

Strong adaptability: It can process parts of various materials and shapes, with high flexibility.

Good surface quality: A smooth surface can be obtained through fine processing, reducing friction and wear.

Mature technology: The technology is widely used, and the processing process is easy to control and adjust.

4.Industry Applications

Automotive industry: key parts such as engine blocks, crankshafts, gearbox gears.

Aerospace: aircraft landing gear, engine blades, precision instrument parts.

Mold manufacturing: cavity and core processing of various stamping dies and injection molds.

Medical devices: precision surgical instruments, transmission parts in medical equipment.

Electronics industry: precision connectors, chip heat dissipation components.