Precision CNC Machining for Automotive & New Energy Vehicles: Powering the Future with Precision

As the automotive industry accelerates toward electrification, precision manufacturing has become the backbone of innovation. At Quick Machine, we enable the new energy vehicle (NEV) revolution through CNC machining solutions that deliver uncompromising accuracy for critical EV components — where thermal management, weight reduction, and electromagnetic compatibility define success.

Why NEV Manufacturers Rely on Our CNC Expertise

√ Mission-Critical Precision for EVs

-

Battery enclosures with IP67-sealed tolerance (±0.02mm) preventing moisture ingress

-

Motor housings achieving <10μm concentricity for vibration-free operation

-

Lightweighting solutions that maintain structural integrity (e.g., aluminum battery trays 35% lighter than steel)

√ Future-Proof Production Agility

-

15-day lead time for complex EV cooling plates vs. industry average 30+ days

-

Zero-retooling transitions between prototype validation and 50k-unit batches

√ EV-Specific Material Mastery

|

Material |

Key Applications |

Performance Advantage |

|

A6061-T6 |

Battery trays, e-motor mounts |

High strength-to-weight ratio |

|

Copper C110 |

Busbars, charge ports |

Optimal conductivity (100% IACS) |

|

PEEK GF30 |

Sensor insulators, connectors |

Electromagnetic shielding |

|

Stainless 316L |

Fuel cell bipolar plates |

Corrosion resistance |

CNC Machining: Enabling the EV Ecosystem

Transformative Applications in New Energy Vehicles:

🔋 Battery Systems

-

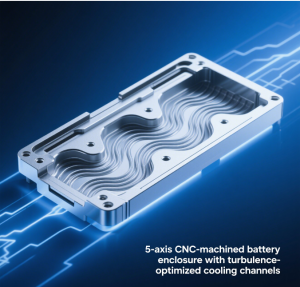

Thermal management plates with turbulence-optimized channels

-

Cell module frames with flame-retardant properties

⚡ E-Powertrain

-

Water-cooled motor housings

-

Reducer gearboxes with <5μm backlash control

🔌 Charging & Power Distribution

-

High-voltage connector bodies (30kV dielectric strength)

-

DC/DC converter enclosures with EMI shielding

Your EV Advantage: Engineered for Electrification

*”The shift to EVs demands machining partners who understand electro-mobility’s unique requirements. Our ISO 9001 & IATF 16949 certified processes ensure every component exceeds AS9100 aerospace standards.”*

— Dr. James Lee, Chief Engineer

Accelerate Your NEV Projects with:

✅ Proven EV Portfolio – 200+ NEV components machined since 2023

✅ DFM for Electrification – Design optimization for thermal expansion/EMC

✅ Full-Vertical Integration – From billet to anodized assembly-ready parts

Your Trusted CNC Partner

With a customer-first approach, state-of-the-art facilities, and a commitment to excellence, Quick Machine is ready to support your automotive projects from concept to completion.

📩 We welcome all inquiries. Contact us today to learn how our CNC machining services can bring your designs to life.